Updated Cut Resistance Rating in Safety Gloves

Many industries rely on safety gloves to protect workers' hands and livelihoods. They are part of the Personal Protective Equipment (PPE) that should be provided by employers, according to the Health and Safety Executive. These gloves also must pass a number of stress tests and adhere to different standards to be rated and deemed safe for workers to use. Because of developments in testing, manufacturing, and materials used, these standards also change to improve the level of protection these gloves offer.

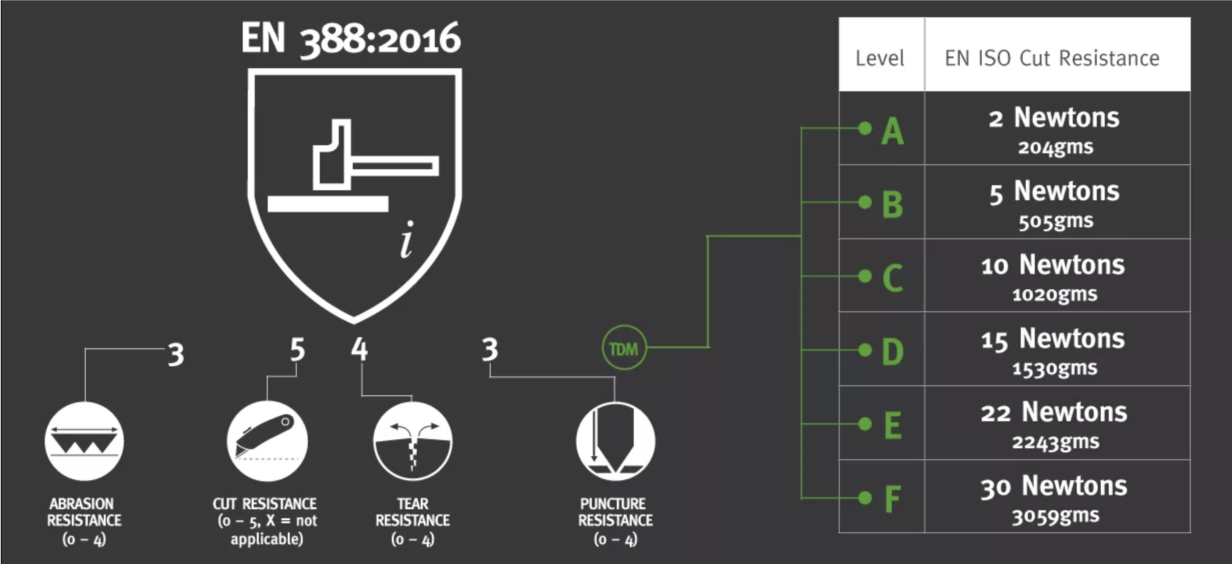

One of the most recent changes in the standards of safety gloves affected its cut resistance rating. By and large, this new way of rating cut resistance can be confusing because of several factors. Let us shed some light on this new rating.

DIN EN 388: 2003

Before we discuss the recent changes, let's investigate the previous rating standard.

DIN EN 388 is the European standard for measuring the gloves' level of protection against possible mechanical risks when conducting work. It describes how gloves are tested and labelled accordingly.

There are four different tests, yielding four different ratings. Gloves are labelled with these ratings to let users know which gloves are ideal for specific tasks.

Resistance to Abrasion

This is tested using sandpaper and pressure on the material of the gloves. The number of cycles needed to create a hole is measured. The highest abrasion resistance rating is 4. This means the material survived 8000 cycles.

Blade cut Resistance

A circular blade is used to cut through the glove at a maintained speed. The index is compared to that of a reference material. The highest rating is 5.

Tear Resistance

This is rated by measuring the force it takes to tear the material of the glove. The highest rating is 4, which means the material takes 75 Newtons of force before it tears.

Puncture Resistance

Testing this requires the glove to be punctured by a nail with an established dimension. The force it takes to puncture the material is measured. The highest rating of 4 can be achieved if the material is not punctured by up 150 Newtons of force.

DIN EN 388: 2016

Because of the constantly improving range of materials used to make gloves, the testing methods need to be updated as well. According to the International Organisation for Standardisation (ISO), a single cut resistance rating test should be applicable to any wearable material. In the new DIN EN 388 system of rating, it is recommended that when gloves offering high levels of cut protection (EN 388: level 4 and 5) are needed, results of the EN ISO 13997 test procedure is adopted. This test is able to measure the amount of force required to cut the material.

Instead of the 0-5 rating in the 2003 standard, the 2016 uses letters between A-F. These letters represent increasing amounts of force with F representing forces of 30 Newtons and above.

Other Standards

The following European standards measure different qualities of materials. Depending on the use, gloves may be rated using two or more standards.

- • EN 374” Protection from chemical risks

- • EN 407” Safety gloves against thermal risks

- • EN 511” Protection from cold

- • EN 16350:2014” Safety gloves, electrostatic properties

At Bryson, we offer a variety of cut protection gloves used for different tasks and industries, as well as in different environments like damp and wet conditions. We show all the cut level ratings right on our website, helping you make the right decision on your gloves protection.

If you want to speak with our knowledgeable staff regarding this topic and others, don't hesitate to give us a call at 020 8660 9119 or send us an email: sales@bryson.co.uk