Update to Standard Regulating Cut Protection Safety Gloves.

The standard EN 388:2003 was used to regulate protection classes of cut resistant safety gloves. The process of constantly further developing materials, such as high performance fibres, requires testing procedures and classifications of these products to be adapted – hence the new revised standard EN388:2016 and ISO 13997.

Our hands are amazingly versatile, allowing us to carry out everyday tasks and precision movements with minimal effort. However, this also means they are exposed to a multitude of hazards in the workplace. Cuts and lacerations are the most common type of hand injury, meaning it is absolutely critical to wear the correct safety glove for the task at hand.

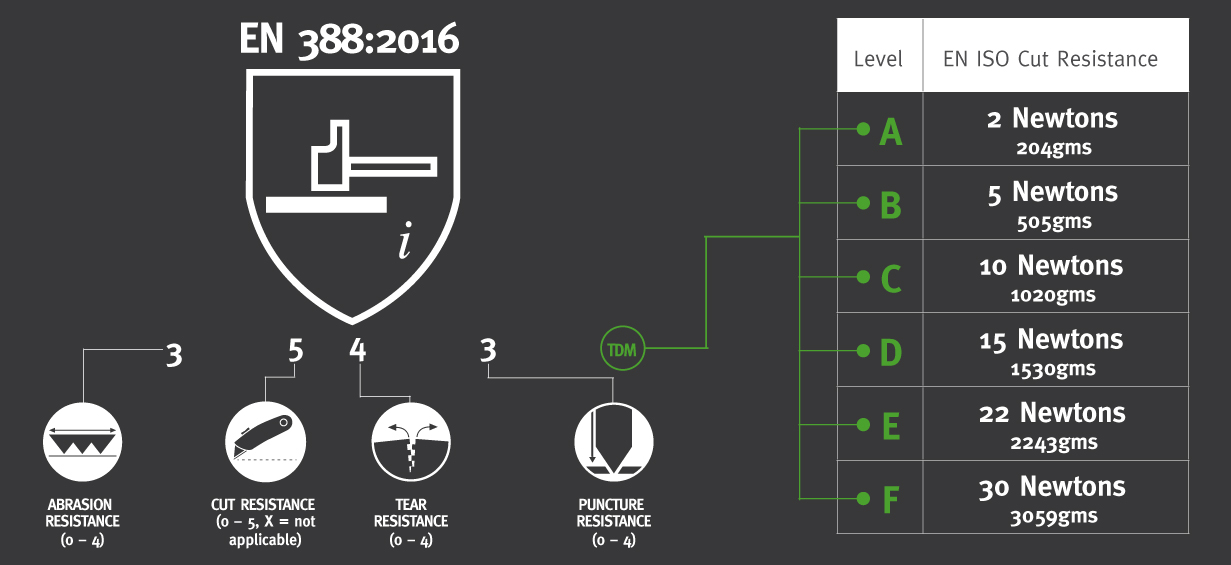

To help users determine a glove’s cut resistance, the EN 388 standard uses index values to rate the performance level of a glove in protecting the user against numerous mechanical risks including:

- - Abrasion

- - Blade cut

- - Tear

- - Puncture

- - Impact

High performance fibres and materials (such as fibreglass or steel) are used to achieve greater levels of cut protection in safety gloves. Due to this, testing procedures and classifications are regularly improved and adapted to ensure the degree of cut level protection is truly representative.

CURRENT TEST METHOD

Up until now, the ‘Coup Blade Cut Test’ has been the standard test method for cut protection. A rotating circular blade moves horizontally to-and-fro across a fabric sample with a fixed force of 5 Newton’s (N) applied from above. The test ends when the blade breaks through the sample material and the result is specified as an index value. This result is determined by the cycle count needed to cut through the sample and additionally by calculating the degree of wear and tear on the blade.

The current method used to test cut-resistance for EN 388 is not ideal for gloves featuring liners blended with steel and glass because the test blade can rapidly become blunt. So now, other data is being considered to provide an additional cut performance indicator - data from the ISO 13997 test.

EN ISO 13997 – A NEW CUT TEST

For safety gloves created with materials designed to have a blunting effect on blades, additional cut protection tests must now be carried out and verified.

Any sample fabric testing for cut resistance using the ‘Coup Blade Cut Test’, which blunts the blade during the test, will have to also be tested using the new EN ISO test. This is to ensure the degree of protection provided by the glove is as accurate as possible.

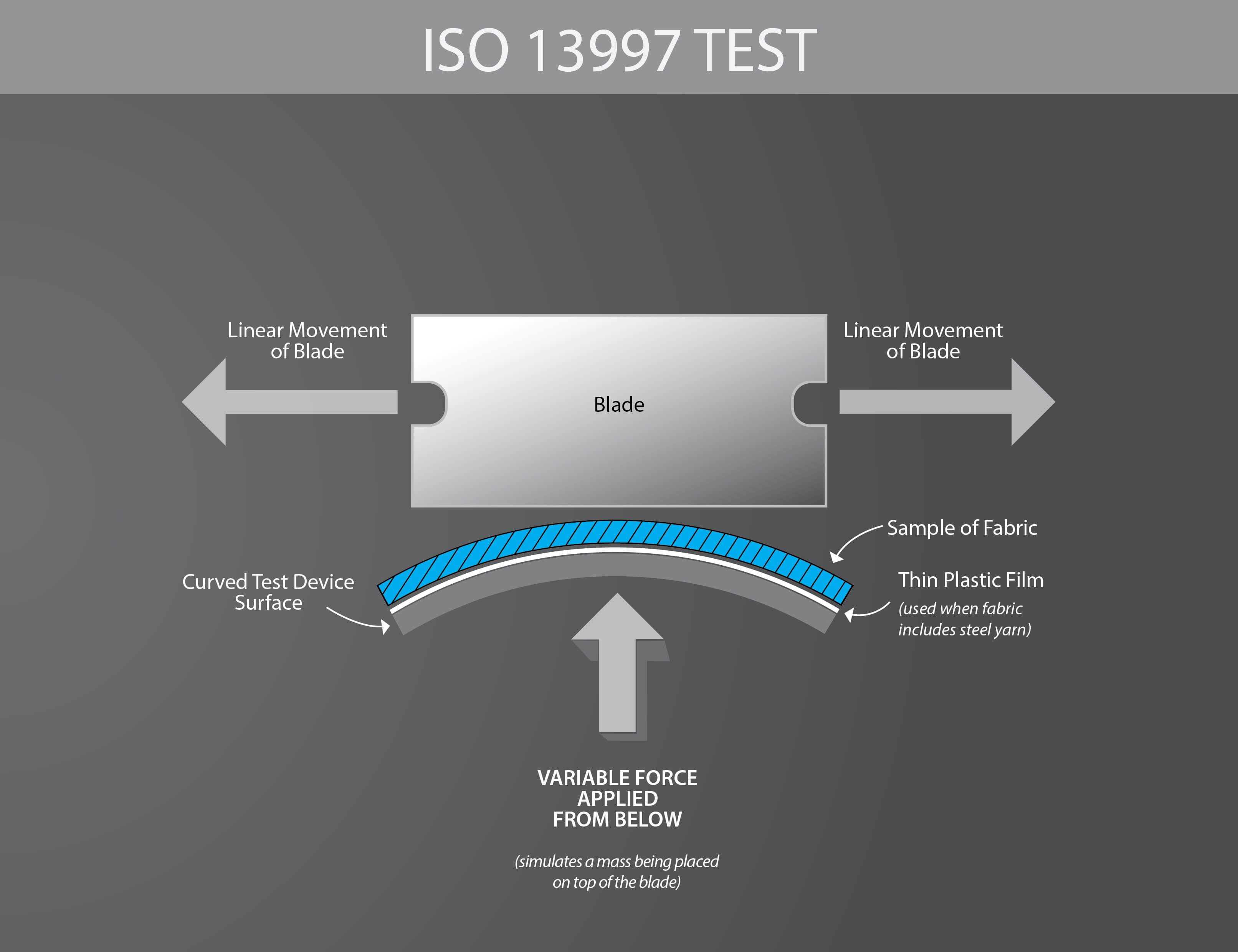

The objective of this new cut protection test is to determine the resistance of the safety glove by applying the sample fabric with great force in a single movement. To this end, a sharp-edged blade is dragged over the sample fabric once. This allows the accurate calculation of the minimum force required to cut the sample material at a thickness of 20mm. The result is displayed in Newton’s. There are 6 cut levels identified in the new EN ISO cut method.

WHATS CHANGING?

The European EN 388 Standard project recommends that when gloves offering high levels of cut protection (EN 388: level 4 and 5) are needed, results of the EN ISO 13997 test method should be considered. This will cross-validate the glove’s cut level performance.

The ISO test methods are expected to be adopted within the EN 388 test method (estimated 2016), when its revision is due, with results categorised and displayed as follows:-

| Level A | Level B | Level C | Level D | Level E | Level F | Level G | Level H | Level I | |

| EN ISO cut resistance in Newton value |

2 | 5 | 10 | 15 | 22 | 30 | 40 | 50 | 60 |

| These Newton values are still to be validated by the European committee | |||||||||

In the future, the additional ISO performance level result may be added as a 5th digit following the existing EN 388 test results under the pictogram.

For example:

HOW IT LOOKS IN PRACTICE & WHAT THE CHANGES MEAN FOR USERS

- - This change only affects new products being certified. All pre-existing EN 388 certifications continue to be valid until a new certification is necessary (max 5 years).

- - Products with higher levels of cut protection can be identified.

- - Accompanying this, the abrasion test method has been revised and the PL31B standardised paper may effect some glove abrasion scores going forward, due to the abradant properties of the paper being more closely controlled. This will provide more accuracy in abrasion performance assessment ratings on all new certification.